Soap surface tension is a fascinating phenomenon that explains why bubbles form, why detergents clean, and how everyday cleaning products work. When soap molecules attach to water, they reduce the cohesive forces between water molecules, lowering the surface tension and allowing air to be trapped in thin films. This simple yet powerful effect is at the heart of everything from a child’s soap bubbles to industrial cleaning solutions. Understanding how soap affects surface tension not only satisfies scientific curiosity but also helps us choose the right products for household and professional use.

Understanding Soap Surface Tension

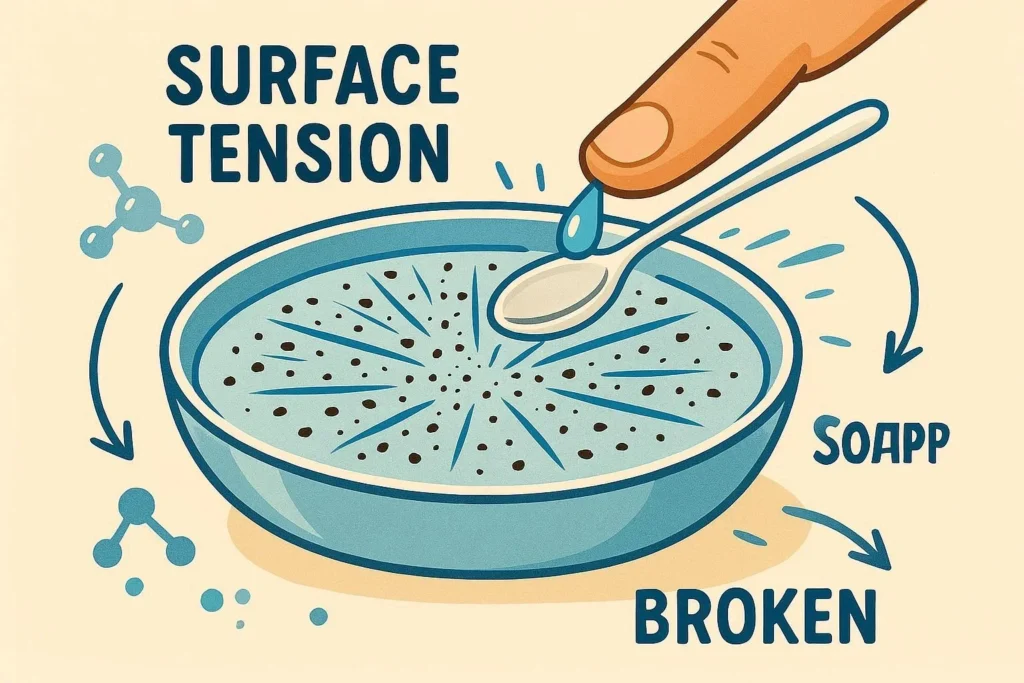

Surface tension is the force that makes the surface of a liquid behave like a stretched elastic sheet. In pure water, hydrogen bonds create a high surface tension of about 72 mN/m at room temperature. Soap molecules, or surfactants, have a hydrophilic (water‑friendly) head and a hydrophobic (water‑repelling) tail. When they enter the water, the hydrophobic tails orient away from the surface, while the hydrophilic heads remain in contact with the water. This arrangement disrupts the hydrogen bonding network, effectively pulling the surface apart and reducing the tension. The result is a more flexible surface that can accommodate bubbles and spread more easily over surfaces.

Scientists measure this reduction using tensiometry, a technique that quantifies the force required to pull a ring or a plate through the liquid. The lower the measured value, the more effective the soap is at lowering surface tension. This property is why a few drops of dish soap can turn a stubborn grease film into a clean, slick surface that water can easily wet.

How Soap Surface Tension Lowers Bubble Stability

Bubbles are essentially thin films of liquid that trap air. The stability of a bubble depends on the balance between the internal pressure of the air and the surface tension pulling the film inward. In pure water, the high surface tension causes bubbles to collapse quickly. Soap molecules reduce this tension, allowing the film to stretch further before snapping. However, the same reduction also makes the film more elastic, which can paradoxically make bubbles more fragile if the surfactant concentration is too low. Optimal bubble formation requires a delicate balance: enough surfactant to lower tension but not so much that the film becomes overly elastic.

In addition to lowering tension, soap molecules form a protective layer around the bubble, preventing water from evaporating too quickly. This layer also reduces the rate at which the bubble’s surface can rearrange, giving it a longer lifespan. The interplay between surface tension, surfactant concentration, and environmental conditions (temperature, humidity) determines how long a bubble will float before bursting.

Measuring Soap Surface Tension in the Lab

To quantify how different soaps affect surface tension, researchers use several standard methods:

- Wilhelmy Plate Method – A thin plate is dipped into the liquid, and the force required to pull it out is measured.

- Du Noüy Ring Method – A ring is lowered onto the surface, and the force needed to detach it is recorded.

- Capillary Rise Method – The height to which a liquid rises in a narrow tube is related to its surface tension.

- Drop Weight Method – The weight of a droplet hanging from a needle is used to calculate tension.

Each method has its advantages and limitations, but all rely on the fundamental principle that surface tension is the force per unit length acting along the liquid’s surface. By comparing the measured values for water alone versus water with added soap, scientists can determine the exact reduction in tension and correlate it with bubble formation efficiency.

Practical Applications of Soap Surface Tension

Beyond the science of bubbles, soap surface tension has real‑world implications:

- Cleaning Efficiency – Lower surface tension allows detergents to penetrate porous surfaces and lift dirt more effectively.

- Industrial processes – In metal plating, paint manufacturing, and textile treatment, controlling surface tension ensures uniform coatings.

- Medical Applications – Surfactants are used in drug delivery systems to create stable emulsions and aerosols.

- Environmental Impact – Understanding how soaps interact with water bodies helps in assessing their ecological footprint.

For example, the National Institute of Standards and Technology provides guidelines on surfactant formulations that balance cleaning power with environmental safety. Similarly, the Wikipedia entry on surface tension offers a concise overview of the physics involved, while the Chemistry World publishes cutting‑edge research on novel surfactants.

In everyday life, the choice of soap can dramatically affect how well your dishes come out sparkling. A high‑quality dish soap with the right surfactant blend will reduce surface tension enough to lift grease but not so much that it leaves a film behind. For industrial cleaners, manufacturers often tailor the surfactant mix to target specific contaminants, ensuring that the surface tension is optimized for the task at hand.

Conclusion: Harnessing Soap Surface Tension for Better Results

Soap surface tension is more than a laboratory curiosity; it is the key to efficient cleaning, stable bubble creation, and countless industrial applications. By understanding how surfactants lower the cohesive forces in water, we can make smarter choices about the products we use and the processes we design. Whether you’re a science enthusiast, a professional cleaner, or simply curious about the physics behind your soap bubbles, mastering the concept of soap surface tension opens up a world of practical benefits.

Ready to elevate your cleaning routine? Discover how soap surface tension can transform your household and industrial processes—contact us today for expert guidance and tailored solutions!

Frequently Asked Questions

Q1. What is soap surface tension?

Soap surface tension refers to the reduction of the cohesive forces at the water surface caused by surfactant molecules. These molecules have a hydrophilic head and a hydrophobic tail, which disrupt hydrogen bonding and lower the surface tension. This effect allows bubbles to form and detergents to spread more easily.

Q2. How does soap lower surface tension?

When surfactants enter water, their hydrophobic tails orient away from the surface while the hydrophilic heads stay in contact with water. This arrangement breaks the hydrogen bonds between water molecules, pulling the surface apart and reducing tension. The result is a more flexible surface that can accommodate bubbles and spread over surfaces.

Q3. Why are bubbles more stable with soap?

Lower surface tension reduces the inward pull on the bubble film, allowing it to stretch further before rupturing. Additionally, surfactants form a protective layer that slows evaporation and rearrangement of the film, extending bubble life. However, too much surfactant can make the film overly elastic and fragile.

Q4. What lab methods measure soap surface tension?

Common techniques include the Wilhelmy plate, Du Noüy ring, capillary rise, and drop weight methods. Each measures the force required to pull a plate or ring from the liquid surface, or the height a liquid rises in a tube, to calculate surface tension. Comparing values with and without soap reveals the reduction caused by surfactants.

Q5. How does soap surface tension affect cleaning?

Lower surface tension allows detergents to wet porous surfaces, penetrate dirt, and lift grease more effectively. In industrial processes, controlling surface tension ensures uniform coatings in painting, plating, and textile treatment. Understanding this property helps choose the right soap for household or professional use.